Industrial Hygiene Program

Development and implementation of a comprehensive program that ensures routine health hazard evaluation and control in your facility.

Industrial Hygiene Risk Assessment

Identification and assessment of health risks and control priorities. The end result is an inventory of health hazards in the workplace and their subsequent controls.

Noise Monitoring and Control

Evaluation of personal noise exposure and identification of areas of excessive noise in a facility. Data is used to develop or improve hearing conservation programs.

Walkthrough Surveys

Walkthrough surveys help to identify unknown health hazards, initiating the process of evaluation and control.

Ventilation Assessment

An assessment helps to ensure that the important engineering control is performing as expected to protect the health of employees.

Ergonomics Assessment

Evaluation of workstations or tasks to identify ergonomic risks and provides solutions to reduce or control them.

Indoor Air Quality Testing

Identification and resolution of indoor air quality issues.

Asbestos Survey and Program

A survey identifies potential asbestos containing materials (ACM) in a facility. Consequent program development assists in managing ACM and personnel exposure.

Exposure Monitoring and Assessment

Evaluate the extent of employee exposure to harmful substances such as benzene, toluene, ethyl benzene, xylene, crystalline silica, formaldehyde, welding fume, diesel exhaust, dusts, volatile organic compounds. This ensures compliance to regulatory occupational

exposure limits (OEL) and allows employers to assess their existing controls and work practices.

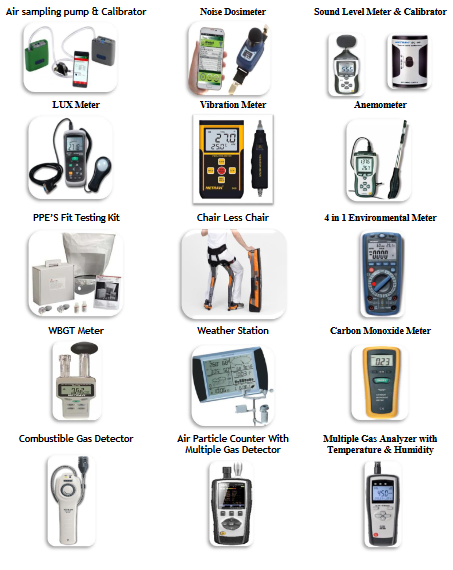

Industrial Hygiene & Safety instruments

Our Esteemed Clients With Our Associated Partners